7March 2024

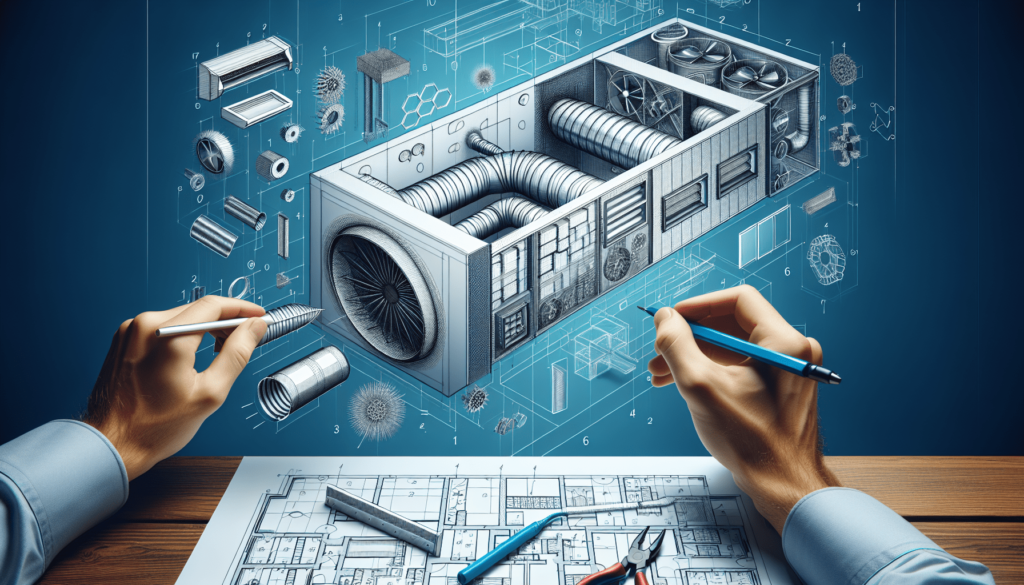

Are you considering installing an air conditioning system in your home, but unsure about the ductwork design and installation process? Look no further! This Beginner’s Guide to Air Conditioning Ductwork Design and Installation is here to provide you with all the essential information you need. Whether you’re a total novice or just need a refresher, this guide will walk you through the basics of ductwork design, helping you make informed decisions and ensure optimal cooling efficiency in your home. Get ready to embark on your air conditioning journey with confidence!

Understanding Air Conditioning Ductwork

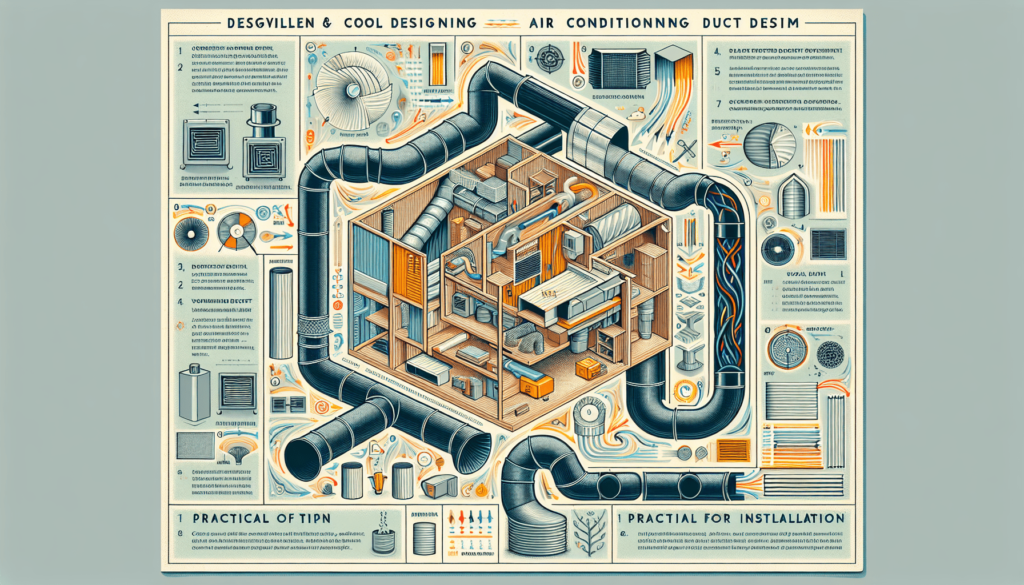

The role of ductwork in air conditioning systems

Ductwork plays a crucial role in air conditioning systems by distributing the conditioned air throughout a building or space. It acts as a pathway, allowing the air to travel from the air conditioning unit to different rooms or areas. Without ductwork, the cool or warm air produced by the air conditioner would not be able to reach all areas effectively.

Types of air conditioning ducts

There are several types of ducts commonly used in air conditioning systems. The most common types include flexible ducts, metal ducts (such as sheet metal and spiral ducts), and fiberglass duct board. Each type has its own advantages and considerations, depending on factors such as cost, installation requirements, and space limitations.

Common materials used in ductwork

Ductwork can be made from various materials, each with its own characteristics and suitability for different purposes. Some common materials used in ductwork include galvanized steel, aluminum, fiberglass, and flexible plastic. These materials have different properties in terms of durability, corrosion resistance, and thermal insulation. The choice of materials depends on factors such as the intended use, environmental conditions, and budget considerations.

Fundamentals of Ductwork Design

Importance of proper ductwork design

Proper ductwork design is essential for ensuring optimal performance and efficiency of an air conditioning system. It involves the systematic planning and layout of ducts to deliver the right amount of air to each room or space. A well-designed ductwork system can help minimize energy loss, prevent air leakage, and maintain a balanced distribution of conditioned air.

Key principles in ductwork design

In ductwork design, several key principles need to be considered. One important principle is the concept of pressure drop, which refers to the decrease in air pressure as it flows through the ducts. Minimizing pressure drop is crucial to maintain adequate air flow and prevent unnecessary strain on the air conditioning system. Other principles include proper sizing, maintaining optimal air velocity, and ensuring adequate insulation.

Effects of ductwork design on air conditioning efficiency

The design of ductwork directly affects the efficiency of an air conditioning system. Poorly designed ducts can result in inadequate cooling or heating, uneven temperature distribution, and increased energy consumption. By considering factors such as duct size, layout, and insulation, proper ductwork design can help maximize efficiency, reduce operating costs, and enhance indoor comfort.

Steps in Planning Ductwork Layout

Evaluating the building structure

Before planning the layout of ductwork, it is crucial to assess the building structure. This involves understanding the floor plan, ceiling height, wall construction, and any obstructions that may affect the duct installation. Evaluating the building structure helps identify potential challenges and determine the most efficient path for the ductwork.

Calculating heating and cooling load

To plan the layout of ductwork, it is important to calculate the heating and cooling load for each room or area. Heating and cooling load refers to the amount of heat that needs to be removed or added to maintain a desired indoor temperature. By accurately calculating the load, the required air flow rates can be determined, which in turn helps determine the size and layout of the ducts.

Determining the ductwork route

Once the building structure and load calculations are assessed, the next step is to determine the route of the ductwork. This involves identifying the start and end points, as well as the intermediate supply and return air outlets. The route should be planned to minimize bends, optimize air flow, and ensure that the conditioned air reaches all areas effectively.

Planning for the necessary air flow

Proper air flow is crucial for effective cooling and heating. When planning the ductwork layout, it is important to consider the required air flow for each room or area. This involves determining the appropriate size and length of the ducts, as well as the necessary number and location of supply and return air outlets. By planning for the necessary air flow, optimal comfort and energy efficiency can be achieved.

Selection of Suitable Duct Materials

Criteria for selecting duct materials

When selecting duct materials, several criteria should be considered. These include the type of air conditioning system, the intended use of the ductwork, cost considerations, and environmental factors. Additionally, factors such as durability, ease of installation, and maintenance requirements should also be taken into account.

Pros and cons of different duct materials

Different duct materials have their own advantages and considerations. For example, galvanized steel is durable and resistant to corrosion, making it suitable for commercial applications. Aluminum, on the other hand, is lightweight and easy to install, making it a popular choice for residential use. Fiberglass duct board provides excellent thermal insulation properties, while flexible plastic ducts offer flexibility and ease of installation. It is important to weigh the pros and cons of each material and choose the most suitable option for the specific requirements.

Considerations for durability and maintenance

Durability and maintenance requirements are important considerations when selecting duct materials. For instance, galvanized steel and aluminum are generally more durable and require less maintenance compared to fiberglass or flexible plastic ducts. However, fiberglass ducts may require occasional inspection for moisture or mold growth, while flexible plastic ducts may need to be replaced more frequently due to wear and tear. It is important to choose a material that can withstand the specific environmental conditions and requirements of the building.

Size Determination of Ductwork

The importance of accurate sizing

Accurate sizing of ductwork is crucial for maintaining optimal air flow and efficient operation of the air conditioning system. Undersized ducts can result in reduced air flow, lower comfort levels, and increased energy consumption. On the other hand, oversized ducts can lead to excessive air flow, noise, and increased energy costs. It is essential to accurately determine the size of the ducts based on the specific heating and cooling load requirements of each room or area.

Factors affecting duct size

The size of the ductwork is influenced by several factors. These include the distance from the air conditioning unit to the room or area, the desired air flow rate, the type and construction of the duct material, and the presence of any obstructions or bends in the duct system. By considering these factors, the appropriate duct size can be calculated to ensure proper air flow and balanced distribution.

Methods for calculating duct size

There are various methods for calculating the size of ductwork. One commonly used method is the friction loss method, which takes into account the pressure drop and air velocity in the ducts. This method involves calculating the equivalent length of the ducts, taking into account fittings, bends, and other obstructions. Another method is the velocity method, which determines the duct size based on the required air velocity. It is important to consult with HVAC professionals or refer to industry standards to ensure accurate calculations and proper sizing.

Proper Ductwork Installation Technique

Tools needed for ductwork installation

Proper installation of ductwork requires a selection of essential tools. These tools may include tin snips, duct crimpers, pliers, screwdrivers, tape measure, wire cutters, and a drill. Additionally, it is important to have appropriate safety equipment, such as gloves, safety glasses, and a dust mask, to protect the installer from any potential hazards. Having the right tools and equipment on hand ensures a smooth and efficient installation process.

Step-by-step ductwork installation process

The installation of ductwork follows a step-by-step process to ensure proper alignment, secure connections, and efficient operation. The process typically involves measuring and cutting the ducts to the appropriate lengths, fitting and securing the connectors, and sealing the joints using approved sealants or tapes. It is important to follow the manufacturer’s instructions and any applicable building codes during the installation process.

Safety precautions during installation

During ductwork installation, it is important to prioritize safety. Proper safety precautions should be followed to prevent injuries and ensure a safe working environment. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against sharp edges and any potential debris. Additionally, care should be taken to avoid electrical hazards and to avoid any contact with hazardous materials. Adhering to safety guidelines helps to minimize risks and ensure a successful installation.

Sealing and Insulating Ductwork

Why sealing and insulation is important

Sealing and insulation of ductwork are essential for optimal performance and energy efficiency. Proper sealing helps prevent air leakage, which can result in energy loss and decreased system efficiency. Insulating the ducts helps maintain the desired temperature of the air as it travels through the ductwork, preventing any unwanted heat gain or loss. Furthermore, sealing and insulating ductwork can also improve indoor air quality and reduce the risk of moisture or mold growth.

Different types of duct sealing techniques

There are different techniques for sealing ductwork, depending on the type of duct material and accessibility. Common sealing methods include using mastic or metal tape to seal the joints and connections, applying duct sealant to any gaps or cracks, and insulating the ducts with insulation sleeves or wraps. It is important to ensure that the sealing materials used are compatible with the duct material and meet the necessary fire and safety requirements.

Choosing the right insulation for your ductwork

Selecting the appropriate insulation for ductwork depends on factors such as the type of duct material, environmental conditions, and desired thermal resistance. Insulation materials commonly used for ductwork include fiberglass, foam board, and reflective insulation. Fiberglass insulation is effective in reducing heat loss or gain, while foam board insulation offers excellent thermal resistance and moisture resistance. Reflective insulation helps to minimize heat transfer through radiation. It is important to choose insulation that meets the necessary fire and safety codes and provides the desired level of thermal protection.

Understanding Air Flow and Balance in Ductwork

Concepts of air flow and balance

Air flow refers to the movement of air through the ductwork system. It is important to ensure adequate air flow to provide effective cooling or heating throughout the building. Air balance, on the other hand, refers to maintaining a balanced distribution of air to different rooms or areas. Proper air balance ensures consistent comfort levels and prevents hot or cold spots within the building.

Implications of unbalanced air flow

Unbalanced air flow in ductwork can lead to various issues. Some rooms may receive insufficient air flow, resulting in inadequate cooling or heating. Other areas may experience excessive air flow, leading to discomfort and energy waste. Unbalanced air flow can also put unnecessary strain on the air conditioning system, leading to reduced efficiency and increased operating costs. It is important to address any air flow imbalances to maintain optimal performance and comfort.

Methods to achieve balanced air flow

Achieving balanced air flow requires careful planning and implementation. Several methods can be used to achieve balanced air flow, including adjusting damper positions, resizing or relocating vents, and installing additional supply or return air outlets. Additionally, regular maintenance and inspection of the ductwork system can help identify and address any issues that may affect air flow and balance. Consulting with HVAC professionals can provide valuable insight and guidance in achieving balanced air flow.

Maintenance and Cleaning of AC Ductwork

Proper maintenance routines for AC ductwork

Regular maintenance of AC ductwork is essential for ensuring optimal performance and maximizing the lifespan of the system. Some key maintenance routines include inspecting the ducts for any signs of damage or air leakage, cleaning or replacing air filters, and checking for proper insulation and sealing. Additionally, any obstructions or debris should be removed to ensure unrestricted air flow. It is advisable to establish a regular maintenance schedule and follow manufacturer recommendations for maintenance procedures.

When and how to clean AC ductwork

Cleaning AC ductwork may be necessary in certain situations, such as when there is excessive dust or debris accumulation, or when there are signs of mold or microbial growth. Cleaning methods may vary depending on the type of duct material and severity of the contamination. Professional duct cleaning services may be required for more extensive cleaning. It is important to consult with HVAC professionals to determine the appropriate cleaning methods and frequency for the AC ductwork.

Signs that your ductwork needs attention

There are several signs that indicate that your ductwork may need attention. These include reduced air flow, inconsistent temperature distribution, increased energy costs, excessive dust or debris in the air, and musty or unpleasant odors. If any of these signs are observed, it is important to inspect and address the ductwork issues promptly. Regular inspection and maintenance can help detect and resolve any problems before they become more serious.

Dealing with Common Ductwork Problems

Identifying common ductwork problems

Ductwork problems can arise due to various reasons, including poor installation, lack of maintenance, or natural wear and tear. Some common problems include air leaks or gaps in the ducts, improper insulation or sealing, obstructions in the duct system, and corrosion or deterioration of the duct material. Identifying these problems is essential for implementing the appropriate solutions and ensuring optimal performance of the air conditioning system.

Troubleshooting ductwork issues

Troubleshooting ductwork issues requires a systematic approach. The first step is to visually inspect the ductwork for any signs of damage, air leaks, obstructions, or improper insulation. Any visible issues should be addressed, such as sealing gaps or repairing damaged sections. If the issue persists, further investigation may be required, such as using specialized equipment to detect air leaks or conducting airflow measurements. It is important to consult with HVAC professionals to accurately diagnose and troubleshoot ductwork problems.

When to call a professional for ductwork problems

While some ductwork issues can be resolved with basic maintenance or repairs, certain problems may require the expertise of HVAC professionals. It is advisable to seek professional assistance when facing complex issues such as major air leaks, extensive duct damage, or significant air flow imbalances. HVAC professionals have the knowledge, skills, and specialized tools to accurately diagnose and address ductwork problems, ensuring the optimal performance of the air conditioning system.

In conclusion, understanding air conditioning ductwork is crucial for designing and installing an efficient and effective HVAC system. Proper ductwork design, selection of suitable materials, accurate sizing, and correct installation techniques are all key factors in achieving optimal performance, energy efficiency, and indoor comfort. Regular maintenance, inspection, and prompt resolution of any issues can help prolong the lifespan of the ductwork system and ensure its reliable operation. By following these guidelines and seeking professional expertise when needed, you can enjoy the benefits of a well-designed and properly installed air conditioning system with efficient and balanced air flow.